Health Food in Powder Packets: Why They Are Becoming the First Choice.

Health food powder packets—the first choice to enter the health care market and grasp health opportunities

The health food market is growing year by year. The development of dosage forms is also becoming more and more diversified. Of all dosage forms, the health food powder package dosage form is the easiest to produce. Its public acceptance, convenience of use, and wide application all make it the most suitable first product choice for starting a health food business.

Benefits of Powdered Dosage Form

Wide application of powdered dosage form- Since the raw materials are all solid powders, physical or chemical changes are unlikely to occur after mixing, and the samples are stable, so a wide range of raw materials can be used.

- Wide range of flavors and acceptability- The powder pack can be made in various flavors according to demand and can be varied in ready-to-eat or brewed form to satisfy multiple target groups.

- More active dose—For example, if you take 5000 mg of active ingredients, one 5-gram packet can be equivalent to 10 capsules.

- Fast development and manufacturing process- There is less uncertainty, shorter development time, and faster time-to-market in the powder pack process.

- Less regulatory restrictions: Compared to dosage forms such as capsules and tablets, they are not strictly regulated in international marketing.

- The powder packets are compact and lightweight.

- It is more convenient to transport across countries or carry around than liquid dosage forms.

The advantages of powder packs have created a mature and aggressive position in the Eastern and Western markets. This advantage, when combined with Welbloom’s one-stop professional service process, saves valuable time and helps you plan the best product for your needs.

=> raw material source control => product quality control => product education training => regulatory certification application

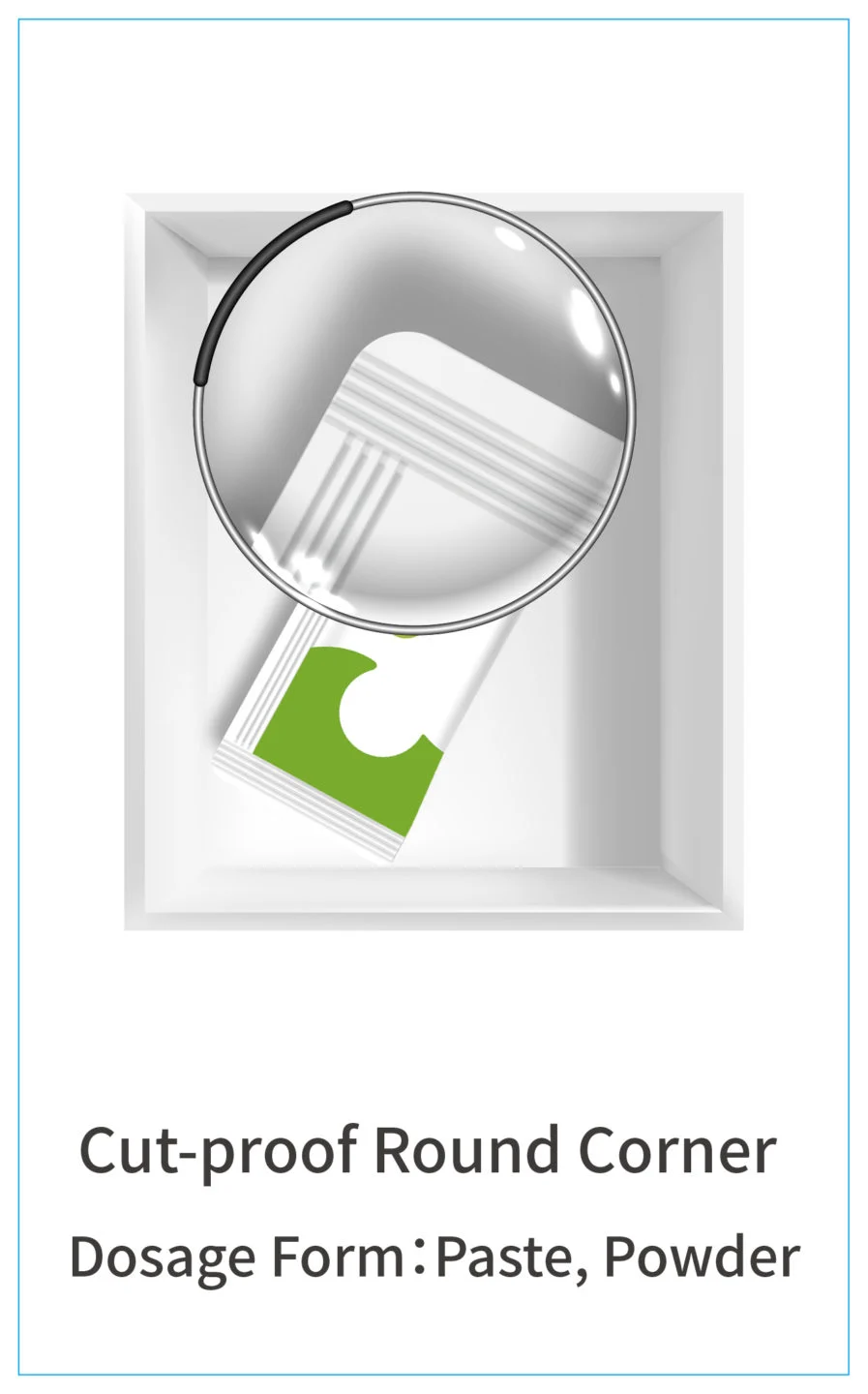

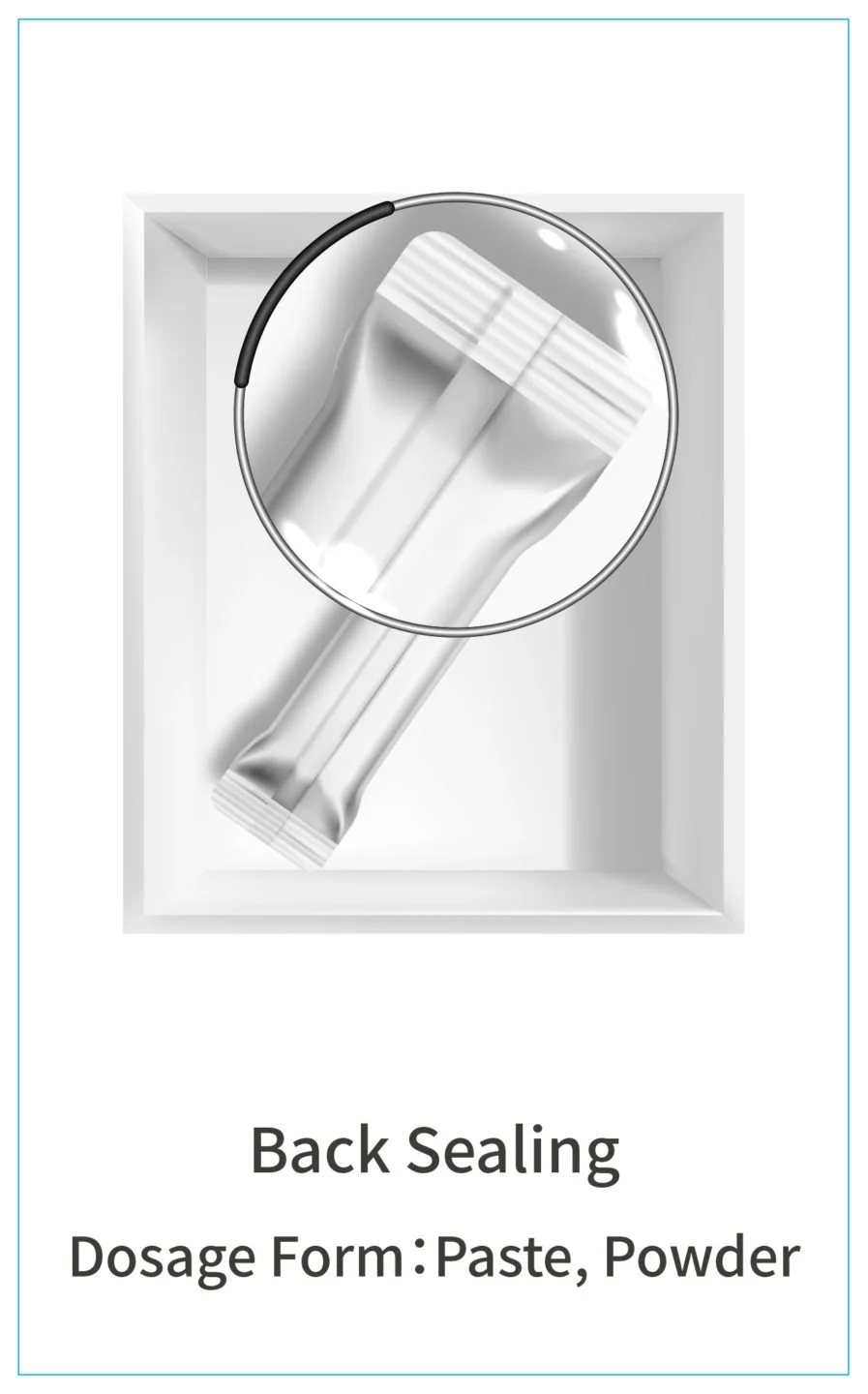

Customized Powder Packaging and Sealing Technology

Different sealing technologies are available: three-sided seal, corner guide, and back seal allowing you to choose different sealing technologies for different customer segments to increase the variation of custom packaging.

- Three-sided seal: the most common sealing method, the seal looks like a “Noah” shape from the back of the finished product, with high utilization of internal space.

- Rounded corners: Rounded corners are not likely to scratch your hands after tearing. The sealing method also reduces the risk of spreading the powder on the ground after tearing.

- Back Seal: Generally designed for long products, the back seal looks like an “I” shape from the back of the finished product and is suitable for brewed packs of less than 10g/pack. Its outlook is both exquisite and beautiful, and the packaging cost is low.

Contact us right away to start creating products: https://wel-en.wp-mak.ing/contactus/

See more healthy food powder pack applications https://wel-en.wp-mak.ing/products/

Wel-Bloom Bio-Tech

Leader of Jelly Supplement

-

Phone +886-2-33225555

-

Fax +886-2-3322-5966

-

Email [email protected]

-

LINE Official Account @welbloom

-

LinkedIn Welbloom BioTech

Contact Us

We will reply them as soon as possible.